Environmental sustainability is our daily commitment that promises a better tomorrow. We continually seek ways to deliver on our promise to protect the planet we call home. With our industry partners, we support uniform recycling initiatives at the local, state and federal level.

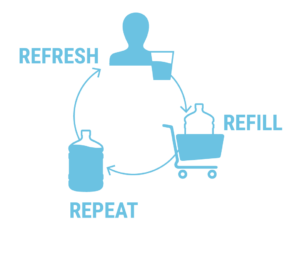

When it comes to packaging, we are focused on reusing, reducing and recycling

Other actions to reduce our impact on the environment are the following:

- Encouraging the disposal of cups into specific bins for recycling purposes

- Using hand-held devices to reduce paper use

- Using internet, emailing and electronic faxing and billing to reduce paper usage

- Recycling all our office paper, newspapers, electronic equipment and batteries

Our focus areas

Environmental, Social and Governance